We are committed to understanding customer needs and providing high-quality, innovative CNC equipment and services to meet customer expectations.

We pursue excellence in quality and ensure that each piece of equipment meets the highest standards by continuously improving our manufacturing processes and quality management systems as well as long-term application and testing.

We value the development and happiness of our employees, provide training and promotion opportunities, and create a positive and healthy working environment.

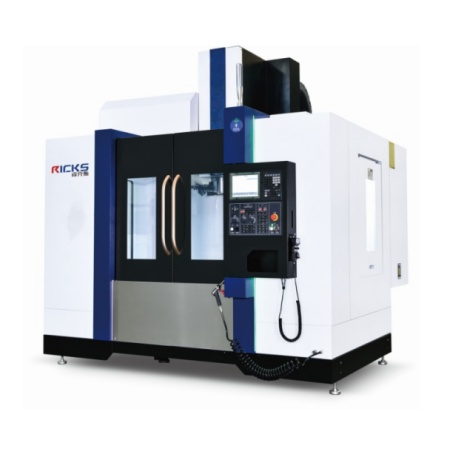

Ricks Precision Machinery Co., Ltd. is a subsidiary of Ruize Machinery which was established in 2007. It specializes in the production of CNC machines. We have established in-depth cooperation with equipment upstream companies, such as hardware factories, sheet metal factories, and casting factories. This allows us to effectively control product quality, delivery time, and costs. By partnering with these reputable companies, we can ensure that our customers receive the highest quality products, on time and within budget.

Combination of linear and hard rails, suitable for processing a variety of material

With power turret, fast and efficient, the best tool to produce multiple processes and complex parts

Designed for precision machining with powerful cutting capabilities

A successful partnership between manufacturers and their clients hinges on effective communications, meticulous analysis, and tailored solutions. Hereby, we delves into the key stages of this collaborative journey, outlining a structured approach that ensures a thorough understanding of customer needs and the delivery of customized CNC metal cutting solutions.

Communicate in depth with customers to understand their metal cutting needs, including materials, thickness, shape, etc. Analyze the customer's production process and existing production equipment to determine the most suitable CNC cutting solution.

Provide customized CNC metal cutting solutions based on customer needs and data analysis. Including CNC cutting machine selection, technical parameters, tool and fixture design, etc.

Provide detailed quotations for customized solutions, including equipment costs, installation costs, training costs, etc. Negotiate with customers, sign a sales contract, and clarify details such as delivery time, payment method, etc.

Start the production and manufacturing process of CNC cutting machines to ensure that the equipment meets customization requirements. Conduct equipment debugging in the factory to ensure that the equipment can operate normally after being installed at the customer site.

Arrange delivery and on-site installation of CNC cutting machines. Provide installation guidance to ensure that the equipment meets design requirements after installation.

Provide customers with CNC cutting machine operation and maintenance training to ensure customers can use the equipment correctly.

Provide remote and on-site technical support to solve problems encountered by customers during use.

Copyright © 2023 Suzhou Ricks Precision Machinery Co.,Ltd., All rights reserved.